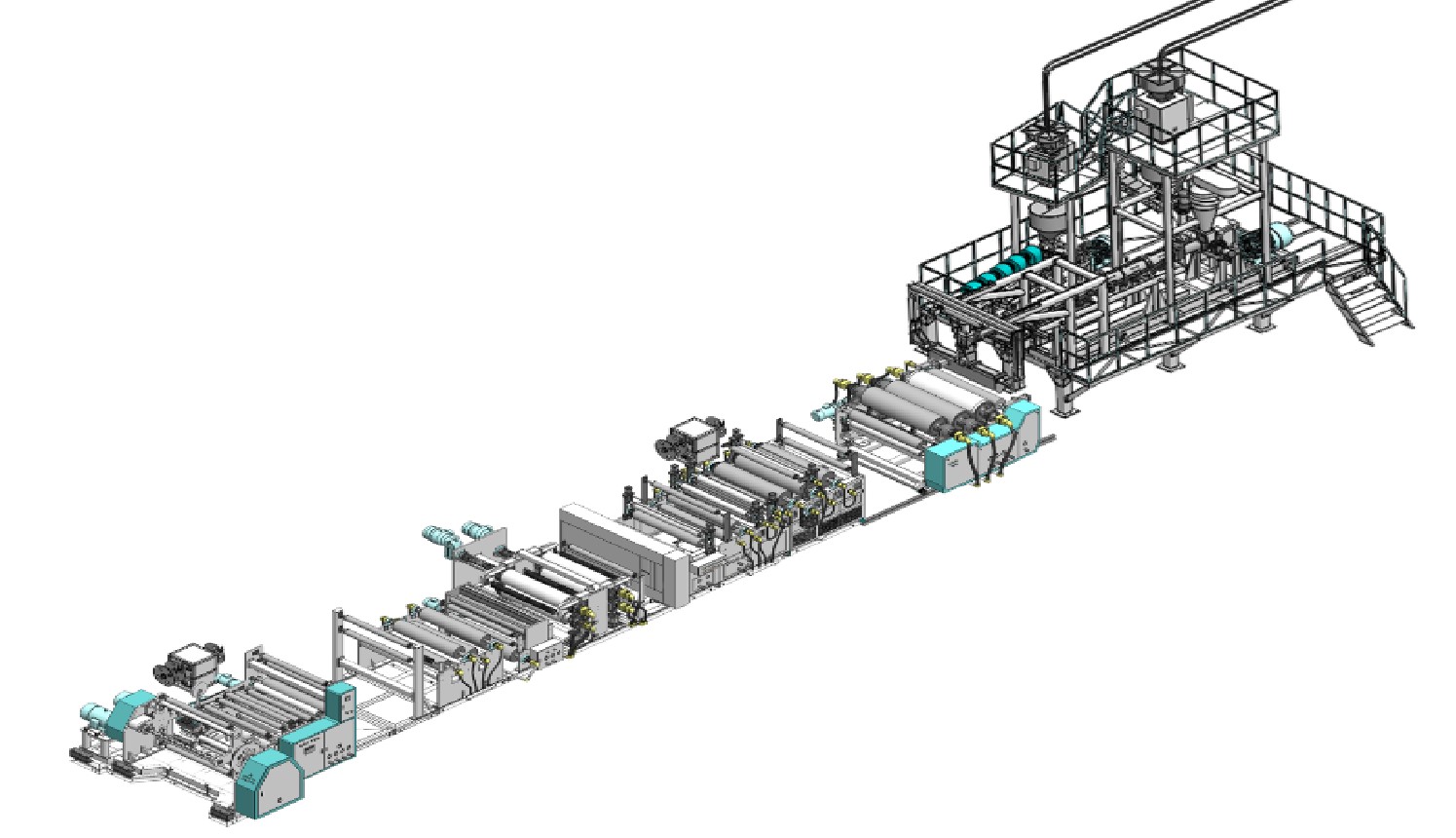

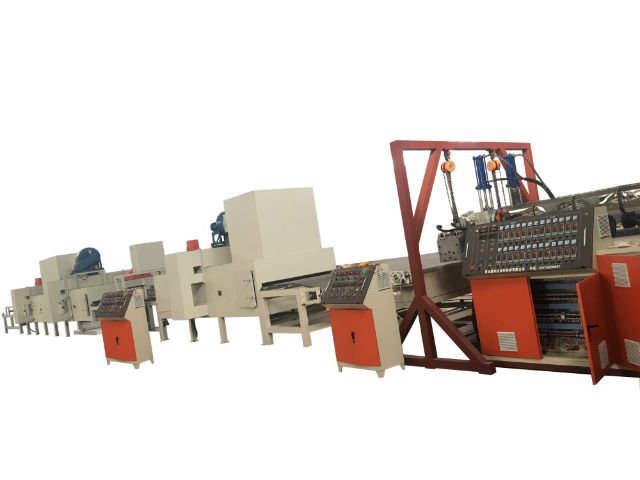

★ The stone paper production equipment adopts the composite flow/calendering production process:

Ingredients, blending, extrusion to produce special masterbatch, and then through extrusion, calendering, stretching, cooling, surface treatment, coating, slitting and winding is the base paper. High production efficiency, good product quality, low production cost, smooth paper surface, especially suitable for printing albums and books.

Stone paper product features:

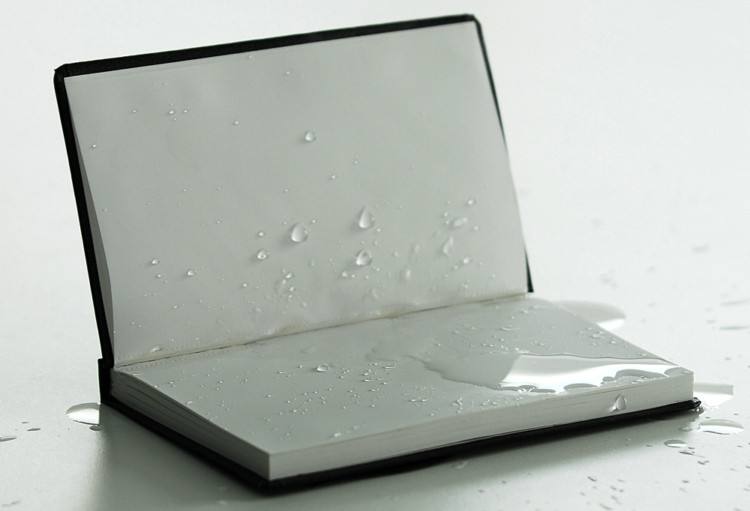

The production process of stone paper is simple, with high output and low energy consumption; it does not use plant fibers and does not cut down trees, which can save a lot of wood and protect the natural ecology; it does not need to add chemical raw materials such as strong acid, strong alkali, bleaching agent, and does not discharge waste water, Waste residue and toxic and harmful gases are green products. The product has good mechanical properties, waterproof, moisture-proof, moth-proof, folding resistance, tear resistance, oil resistance, non-toxic, odorless, non-polluting, stable geometric size, high printing definition, good effect, and can be naturally degraded into powder after use. Natural and other characteristics, widely used in gift packaging, packaging, office supplies, decorative albums and other printed products.

Stone paper is divided into PP and PE, and the material and papermaking method are selected according to the purpose of the paper. The company provides a complete set of solutions, turnkey projects. The stone paper/synthetic paper production line includes three parts: material handling (granulation), drool stretching (papermaking), and coating (paper surface treatment). Provide a complete set of solutions such as plant planning and layout, technical training for stone paper production personnel, a complete set of equipment production lines, stone paper production processes, and formulas for all aspects of stone paper production. We have provided several sets of stone paper turnkey projects for domestic and foreign, and have been widely recognized by customers. The processing methods are divided into: drooling stone paper/synthetic paper production line; uniaxially stretched stone paper/synthetic paper production line; biaxially stretched stone paper/synthetic paper production line.

Application of stone paper: decorative wallpaper, carton, carton, coated paper, cigarette paper, labels, cards, advertising decoration paper, postal paper; special paper, such as field work paper, underwater work paper, underground work paper, special paper, etc. It can be said that the application field is very wide, and with the continuous maturity and upgrading of stone papermaking technology, the application field will be even larger. The cost of stone paper products is 20%-30% lower than that of alternative paper products, and it has strong competitiveness and a very promising market prospect.