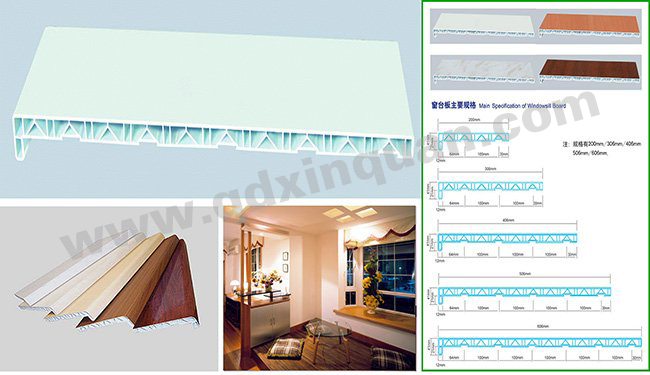

UPVC window sill profile production line

1. Equipment features:

Referring to foreign technology, the optimized design of the unit has the advantages of uniform plasticization, small shear rate, high output and long service life. The unit is composed of a conical twin-screw extruder, a vacuum setting table, a traction machine, a cutting machine, a laminating machine, and a turning frame.

The host adopts imported AC variable frequency drive, and the temperature control instrument adopts Japanese RKC or OMRON products. The auxiliary vacuum pump and traction motor are made of high-quality products, which are easy to maintain. After replacing the screw barrel and mold, the simulated wood foam profile can be directly extruded, and the effect is better than that of a single screw.

2. Technical parameters:

| serial number | describe | parameter |

| 1 | raw material | Recycled PVC materials, additives |

| 2 | window sill size | Width: 600, 700, 800mm |

| 3 | Production line speed | 0.5-1.5 m/min |

| 4 | maximum output | 280kg/h |

| 5 | Line size | 23m × 2.5m × 3m L×W×H |

| 6 | total installed power | 185KW |

| 7 | actual power consumption | 125KW (Approx.) |

| 8 | quality system | ISO9001:2000 |

3. Product Features:

1. Beautiful appearance: PVC window sills have various surface patterns, including solid color series, marble pattern series, wood grain series, etc. The surface gloss is good, the color is soft, and the lines are smooth to make the window sill surface more perfect.

2. Instead of the traditional lead salt formula, the rare earth formula is used as the raw material of the PVC window sill, which improves the physical properties of the product on the one hand, and on the other hand, the formula is low lead, non-toxic, and fully complies with the national health standards.