Plastic Shredder GXS40 series single-shaft shredders are widely used in the crushing and recycling of most waste materials. model Power (kw) Inlet size (mm) Maximum output (kg/hr) GXS4080 37 800×1300 1000 GXS40100 45 1000×1300 1500 GXS40120 55 1200×1300 2000 GXS40150 75 1500×1300 2500 Whether it is a large volume of pipes, profiles, blocks or packed and compressed bottle materials, films, chemical fibers or carpets, the GXS40 series single-shaft shredders can be shredded to the appropriate size. This series of single-shaft shredders has a complete range of models, and there are main shafts and auxiliary equipment with different structures to choose from. GXS2250 and GXS2260 single-shaft shredders are suitable for all kinds of industrial waste, especially the materials with large volume, strong toughness and high hardness that are difficult to be cut by the shredder. For example, the headstock (block) produced by the extruder, aluminum cans, thick-walled pipes, rolls of film and clumps of cables, etc. The low-speed spindle has high cutting force, high output and low energy consumption. The movable knife can be replaced for four times, and it is fastened…

Post-processing equipment for wood-plastic products The post-processing equipment includes wood-plastic products sanding machine, embossing machine, etc., mainly for further finishing of profile sheet products, making them more beautiful and practical. Sanding machine: This machine is mainly suitable for brushing the surface of PE and PP wood-plastic profiles to increase the wood feeling on the surface of the profiles. This machine adopts crawler type transmission, frequency conversion speed regulation, thickness can be adjusted flexibly, and special shape steel wire rolls can also be customized. Embossing machine: It is mainly used for the surface embossing treatment of wood-plastic profiles. After pressing, the surface of the profiles becomes a natural wood grain shape, which enhances the beauty and naturalness of the products. According to the requirements of the product, it can be embossed on one side or on both sides.

The laminating machine is suitable for color lamination on the surfaces of PVC window sills, door panels, foam boards and other plates and profiles; the machine coats polyurethane solvent-based glue, and the glue coating system adopts the method of blade coating. Online operation with extrusion lines is possible. This machine is composed of automatic feeding, high-pressure water cleaning, coating affinity agent, profile preheating, automatic gluing, covering protective film and other mechanisms. This machine adopts Siemens frequency conversion system, Omron temperature control system, worm gear drive, German Schneider low-voltage electrical appliances, and the man-machine interface is operated in Chinese, English and Russian. (optional)

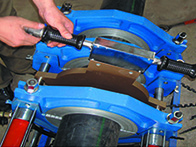

Compound distributor, dehumidification pre-crystallization dryer, vertical drying mixer, single-phase feeder, meter weight feeder, screw feeder, planetary cutting machine, non-crushing cutting machine, traction and cutting integrated machine, color Belt machine, inkjet printer, printing machine, crawler tractor, six crawler tractor, flat belt tractor, plastic sheet welding machine, plastic pipe welding machine