Qingdao Xinquan Plastic Machinery Co., Ltd. participated in the 2013 China Guangzhou Rubber and Plastics Exhibition

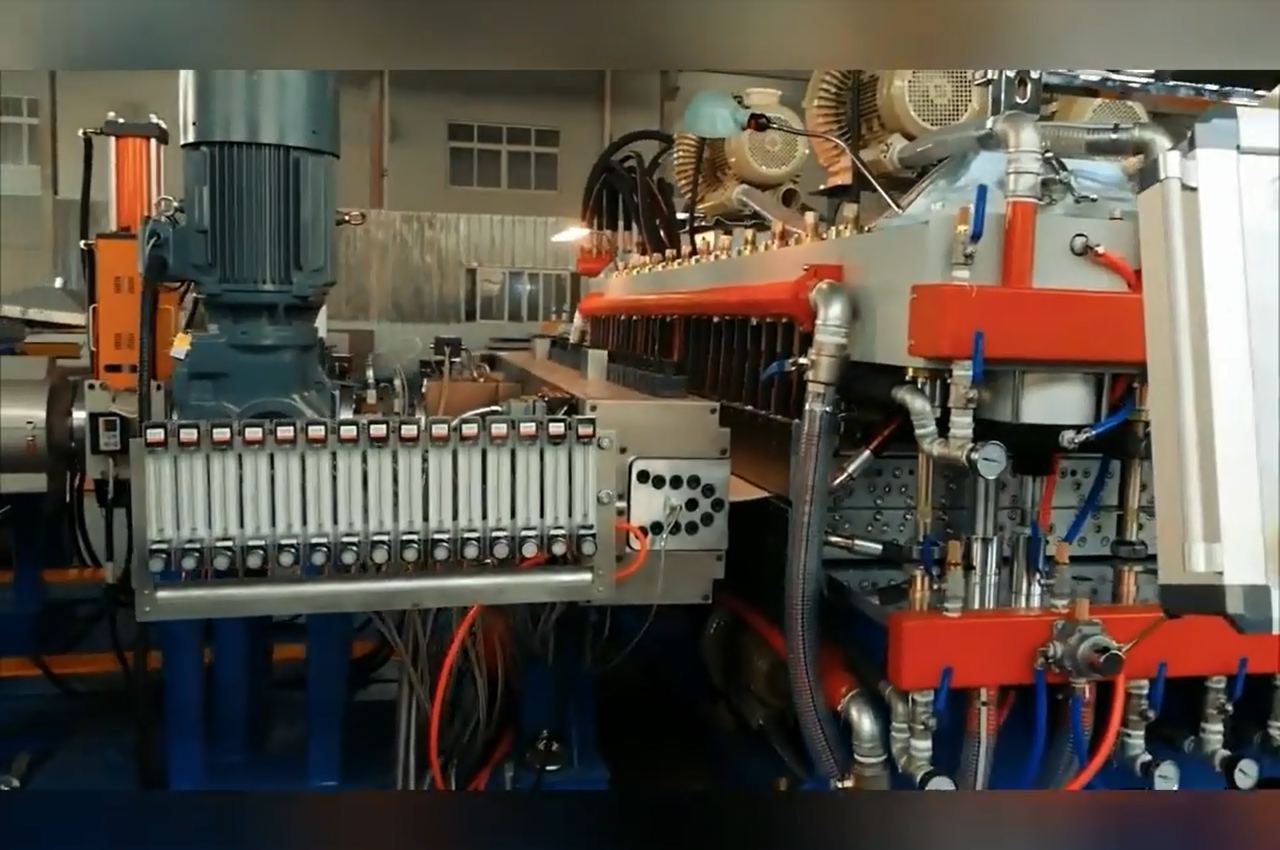

PE, EVA, TPE, POE cast film Note: The width can be customized according to customer's specified requirements; online composite function can be realized technical parameter: model Screw diameter Screw aspect ratio Die width Film size membrane thickness Line speed SJXQ1900 ∮110 36:1 1900mm 1600mm 0.02-0.20mm 30-80m/min SJXQ2300 ∮120 36:1 2300mm 2000mm 0.02-0.20mm 30-80m/min SJXQ2600 ∮135 36:1 2600mm 2300mm 0.02-0.20mm 30-80m/min

Plastic pulverizer The plastic pulverizer is used to grind recycled PVC and PE plastics into powder for reprocessing; The main machine and the overall structure of the pulverizer adopt scientific technology, and the plastic raw materials or pulverized materials with a particle size of 6-10mm are sent to the high-speed grinding chamber through the vibrating feeder to work to form a powder state; the fineness of the powder , particle size distribution, and fluidity can be adjusted by adjusting the gap between the grinding discs. The whole set of pulverizer is equipped with automatic temperature control, vibrating screen and feeder system; the grinding disc has two types: full circle and split type, which can be customized according to the needs of users. It has been proved by the practical operation of the professional factory of plastic products that adding 20%-30% of the grinding powder to the processing formula, the chemical and physical properties of the products remain unchanged from those of the new material. Therefore, it is a supporting equipment for plastic products factories to reduce costs and save expenses to…

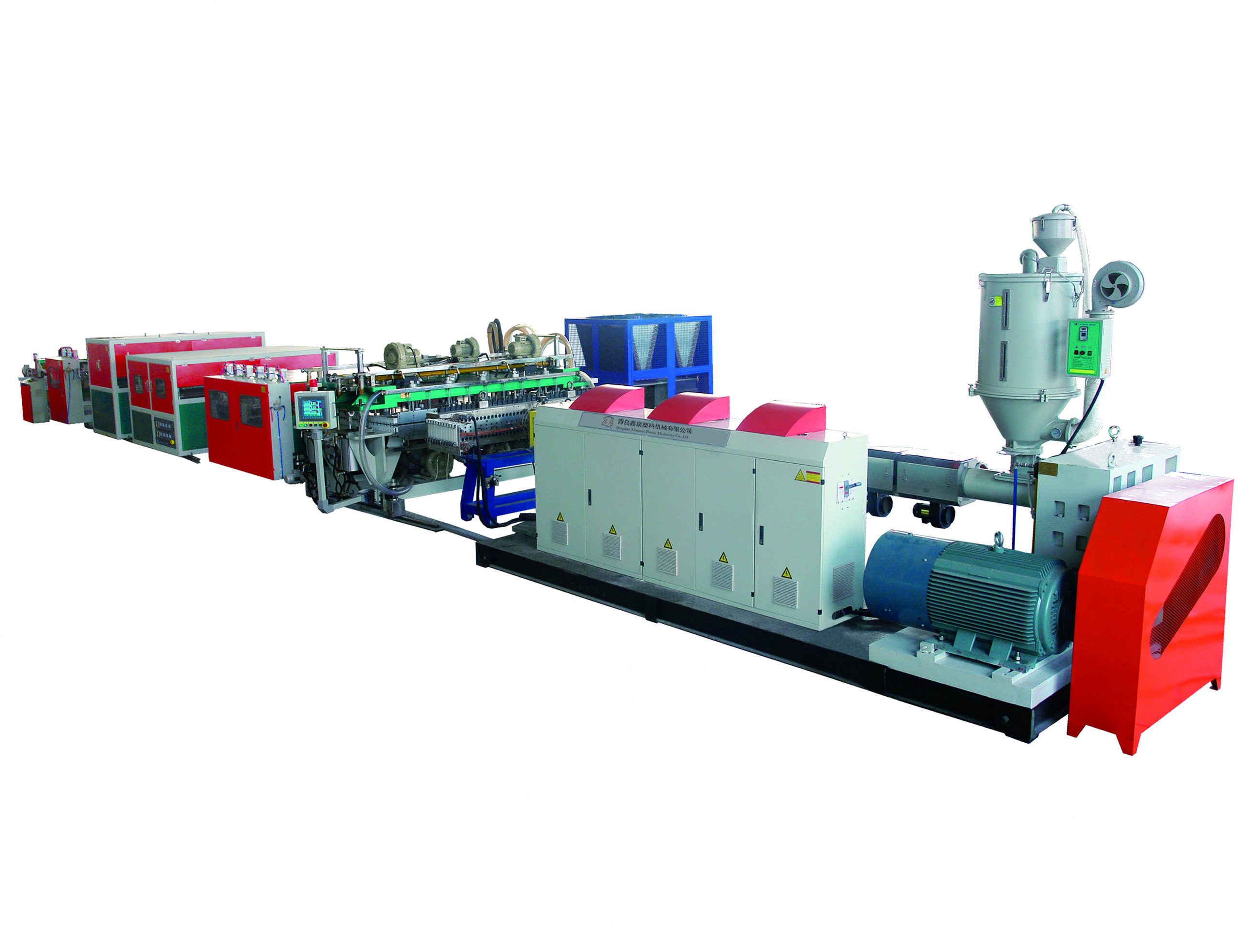

UPVC window sill profile production line 1. Equipment features: Referring to foreign technology, the optimized design of the unit has the advantages of uniform plasticization, small shear rate, high output and long service life. The unit is composed of a conical twin-screw extruder, a vacuum setting table, a traction machine, a cutting machine, a laminating machine, and a turning frame. The host adopts imported AC variable frequency drive, and the temperature control instrument adopts Japanese RKC or OMRON products. The auxiliary vacuum pump and traction motor are made of high-quality products, which are easy to maintain. After replacing the screw barrel and mold, the simulated wood foam profile can be directly extruded, and the effect is better than that of a single screw. 2. Technical parameters: serial number describe parameter 1 raw material Recycled PVC materials, additives 2 window sill size Width: 600, 700, 800mm 3 Production line speed 0.5-1.5 m/min 4 maximum output 280kg/h 5 Line size 23m × 2.5m × 3m L×W×H 6 total installed power 185KW 7 actual power consumption 125KW (Approx.) 8 quality system ISO9001:2000 3. Product Features:…

Stone plastic line production line 1. Production process: mixing—extruder—die—vacuum forming—tractor (optional)—cutting machine—stacker—hot stamping transfer 2. Technical parameters model SJSZ-51 SJSZ-55 SJSZ-65 monitor rate 18.5 30 37 Vacuum pump power KW) 4 5.5 7.5 Traction speed in) 0.5-12 0.5-10 0.5-6 Auxiliary power KW) 54 71 85 Extrusion volume (KG/H) 120 150 250 3. Product use: Lines are suitable for a variety of special-shaped surfaces, such as Roman columns, fireplaces, inside and outside of spiral staircases and other complex and special-shaped surfaces. , anchor lines, etc., can fully meet the needs of various specifications of high-end ceramics in the market. 4. Product Features: Although the imitation marble lines are artificial imitation, the excellent imitation technology will make the finished product have the texture and color of natural marble, beautiful and generous, and there are few artificial traces. At the same time, the imitation jade decorative lines can be widely used in various styles of products such as polished crystal tiles, microcrystalline stones, full polished glaze, and antique tiles, instantly showing the overall space taste. Most of the products are the combination of the…

1. Uses: The wood flour mill produced by our factory is suitable for grinding wood fiber materials. Grind to a fineness of 10-500 mesh at one time. Applicable to: twigs, shavings from furniture factories, bamboo flour, rice husks, peanut husks, rice bran and other crops. The ground powder can be directly mixed with PP, PE, PVC and other plastics to produce wood-plastic products. Equipment advantages: 1. A new type of material can be installed to play the functions of sound insulation and heat dissipation, so the machine has low noise, no vibration, beautiful appearance, strong and durable, high output and greatly improved efficiency during production and use. 2. The feeding port of the wood flour machine adopts self-priming feeding, which can ensure safe production forever, replacing the shortcomings of direct feeding of traditional pulverizers, accidentally throwing metal blocks, and serious damage to the wood flour machine.

High-speed mixing unit SRL series mixers are widely used for mixing, stirring, drying and coloring of various materials in plastics, rubber, dyes, food, daily chemicals and other industries. SRL series mixers are advanced in design, easy to operate, safe and reliable. Small size, light weight, high efficiency, low energy consumption and low noise. Is your ideal purchase product.

PE carbon spiral reinforced pipe production line 1. Features of the production line Equipped with a special single-screw extruder for polyolefin, which has the characteristics of high-speed extrusion, high-speed acceleration, etc.; specially designed sizing cooling method: production range 50-200mm; the best design for low melting temperature, the internal stress of the pipe is small, and the internal and external Smooth surface; high flexibility, suitable for co-extrusion of all polyolefin materials, can extrude two-layer, three-layer spiral reinforced pipes with different specifications; the inlet end of the optimized copper spiral sizing sleeve has a pre-cooling device And strong suction and vacuum device, suitable for high-speed extrusion of the pipe; longitudinal movement motor adjustment, three-dimensional adjustment can be achieved up, down, left and right; high-efficiency water pump and special sprinkler head bring efficient spray cooling. 2. Features of PE carbon tube: The PE carbon tube product has a special thread shape, which can be bent freely to bypass obstacles, which is convenient for construction. The length of a single PE carbon tube is determined by the user at will, so as to reduce the…

UPVC double pipe production line 1. Features of UPVC double pipe extrusion line: The products produced by the UPVC double-pipe extrusion production line are mainly used in construction threading pipes, electrical pipes, etc. The first-class quality has been integrated into many years of experience. The main machine adopts a conical twin-screw extruder to improve the mixing effect and the extrusion pressure is high. Double tube extrusion die. High production efficiency and stable molding. Using double-tube vacuum sizing technology, spray cooling to ensure the quality of the tube. Independent control of the overall structure of the double-tube pulling mechanism and synchronous cutting device. The equipment is compact and occupies a small area. 2. Main technical parameters: model SJSZ51/105 Applicable raw materials pvc Extruder Model SJSZ51/105 Diameter range mm 16-50 Motor Power 22kw Maximum extrusion volume 120kg/h Production speedm/min 3-10

PVC Fiber Reinforced Hose Production Line 1. Pipe features and uses: PVC fiber reinforced hose, also known as PVC mesh pipe, commonly known as plastic snakeskin pipe, the hose has many characteristics such as non-toxic, transparent, pressure resistance, stretch resistance, acid and alkali resistance, beautiful appearance, soft and lightweight, durable and so on. It is suitable for the transportation of pressurized or corrosive gases and liquids, and is widely used in machinery, coal mines, petroleum, chemical industry, agricultural irrigation, construction, civil use (solar water heaters, gas tanks) and other fields. It is also widely used in the watering of gardens and lawns. 2. Production line The PVC fiber reinforced hose production line is mainly composed of extruder spray tank, tractor, winding machine, coiler, etc. It has the characteristics of reasonable matching, unique structure, reliable performance, simple operation, convenient maintenance, strong continuous production capacity, etc., and is deeply welcomed and trusted by the majority of users.

UPVC foam inner spiral muffler pipe production line 1. Pipe features and applications: For building drainage pipes. The unique internal helical structure makes the water flow down along the thread, which greatly reduces the noise caused by the water flow. 2. Equipment structure: The main machine adopts the co-extrusion of two twin-screw extruders, and the advanced process formula obtained by many years of practice and experience. The co-extrusion die head can be specially designed, and the solid wall tube, the solid wall inner spiral tube, the foamed tube and the foamed inner spiral tube can be produced at the same time only by changing the mandrel. Replacing the mold can produce nano-antibacterial PVC water supply pipe, hollow wall inner spiral muffler pipe. 3. Technical parameters: Host model: SJSZ-65/22 SJ-SZ-55/22 Production pipe range mm: ∮16-∮160 Production speed: 1-12 m/min

PVC steel wire reinforced hose production line 1. Introduction of production line High-speed and high-efficiency extruder is used to ensure material plasticization quality and output. The specially designed wire spring winding machine has uniform winding spring and long continuous production time. The pipe produced by the specially designed pipe head has high transparency, uniform distribution of steel wires, and the length can be set arbitrarily. The main electrical components of the unit are imported products, and the operation is stable and reliable. All control buttons of the unit are designed in one piece, which is easy and quick to operate. 2. Main technical parameters model XQS45 XQS65 XQS90 SQS120 extruder SJ45/30 SJ65/30 SJ90/30 SJ120/30 Specification range ф12-25 Ф20-50 Ф50-102 Ф75-150 Yield 20-40 40-75 70-130 100-150 Installed power 30 40 50 75